低温拉断装置(拉断阀)解决方案

Cryogenic Breakaway Device(Breakaway Coupling)The solution

一.概述General Description

低温装卸液系统主要由液源站、槽车或者船舶的软管、加液臂、阀门、管路系统连接,接口采用 DN25-DN100接口,或于加液枪或于干式接头或于法兰连接。加液管路上要求配备拉断装置(拉断阀),当连接件尚未脱离,而另一端的车或船或外界移动式设备离开,强大的外力将导致软管或设备的损坏、低温液体的泄漏危机安全事故时,低温拉断装置在紧急状况下及时保护设备和人员的安全而紧急关闭。

下面重点介绍该低温拉断装置的结构原理及应用。

The cryogenic liquid loading and unloading system is mainly connected with the hose of the liquid source station, trailer or ship, refueling arm, valve and pipeline system, and its connector adopts DN25-DN100, connecting to fueling nozzle or dry joint or flange type. A breakaway device (breakaway coupling) is required on the refueling pipeline. When the connector is not separated but the other end of the vehicle or boat or external mobile device separated, strong external force will cause the damage to the hose or equipment. When the leakage of cryogenic liquid occurs, the cryogenic breakaway coupling can protect the safety of equipment and personnel in time and turn off emergently.

The structure principle and application of the cryogenic breakaway device are introduced as below

二.性能参数Performance parameters

1.公称通径Nominal Diameter:DN25---DN100

2.公称压力Nominal Pressure:PN16、PN25、PN40

3.设计温度Design Temperature:-196℃

工作温度:-196℃~+75℃(高温上限 300℃)

Operating temperature: -196℃ ~ +75℃ (Max. Temperature 300℃)

脱离后密封率:根据不同介质设置 95%—100%密封率(管道泄压)

Sealing rate after separation: 95%-100% sealing rate is set according to different media (pipeline pressure relief)

适用范围:液氧、液氮、液氩、液化天然气、乙烯、液氯、等低温、常温介质的气体与液体

Application Media: Liquid Oxygen, Liquid Nitrogen, Liquid Argon, Liquefied Natural Gas, Ethylene, Liquid Chlorine, and other low temperature, room temperature media of gas and liquid

4.材质:壳体采用耐低温的 304或 316L不锈钢材料

Material: the shell is made of 304 or 316L stainless steel

装配前进行深冷处理;密封材料采用耐超低温特氟龙材料,密封面经特殊工艺加工达到密封要求。Cryogenic treatment before assembly; The sealing material is made of cryogenic Teflon material, and the sealing surface is processed by special technology to meet the sealing requirements.

5.壳体密封性:零泄漏;Shell sealing: no leakage;

6.使用性能:Operational performance

1)紧急情况下能够使装卸设备快速脱离;

2)常规操作时不会出现“拉断”;

3)拉断后分开的两部分能有效达到设计密封。

1) In case of emergency, the loading and unloading equipment can be quickly separated;

2) There will be no "break away" happened during routine operation;

3) The two parts separated can effectively achieve the design sealing.

7.流量:管线安装拉断阀后不影响装卸车原有的流量,流通率设计达到球阀流通率级别;不限流、不截流。

Flow rate: the pipeline with breakaway valve does not affect the original flow rate of loading and unloading, flow rate designed reaches the ball valve's flow rate level; Unlimited flow, no interception.

三.结构原理Structure principle

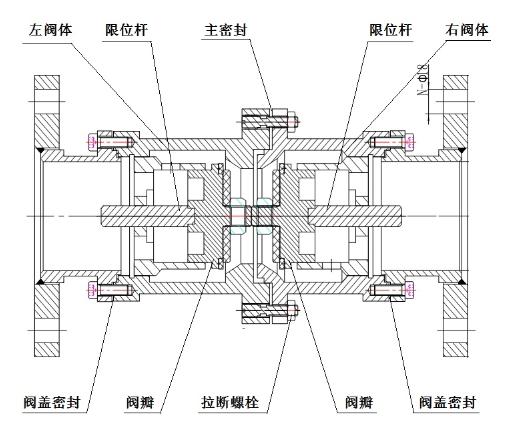

图 1所示为紧急拉断装置的结构图,主要由两个阀体组成,单边阀体的主体均采用弹簧力关闭的结构,其关闭力来自于阀瓣弹簧本身。

PICTURE 1 shows the structure of the emergency breakaway device, which is mainly composed of two valve bodies. The main body of the unilateral valve body adopts spring force closing structure, its closing force comes from the disc spring itself.

图 1紧急拉断装置PICTURE 1 Emergency breakaway device

1.主体结构The main structure

左阀体Left body

右阀体Right body

限位杆Limit lever

阀瓣Disc

主密封Main sealing

阀盖密封Valve bonnet seal

拉断螺栓Breakaway bolt

2.拉断装置由两部分阀体组成,中间为拉断螺栓,两边由独立的单个阀体组成,

主要由壳体、阀瓣、主密封圈、导向板、拉断螺栓、卡簧组成。

The breakaway device consists of two parts of the valve bodys, the middle is the breakaway bolt, and the two sides are composed of an independent single valve body.It is mainly composed of shell, valve disc, main sealing ring, guide plate, breakaway bolt and circlip.

1)壳体拉断螺栓连接左右阀体对接;中间为流通孔,流通面积的设计达到流通

率的要求;导流板作为弹簧和阀芯的支座;拉断装置连接形式采用法兰或焊接方式连接。

Breakaway bolt of shell connects left and right valve bodys, and the middle is the circulation hole, circulation area designed meets the requirements of circulation rate. The guide plate is used as the support of the spring and the valve trim. The connection form of breakaway device adopts flanged or welding type.

2)阀瓣阀瓣为顶针结构,设计限位装置,有利于保证良好的密封性,操作简单,易于维护维修,同时避免阀芯错位不通液现象。

Valve disc is thimble structure with limit device which is designed to ensure good sealing, simple operation, easy maintenance, and avoid the spool dislocation to cause no liquid phenomenon.

3)密封左右阀体中间采用耐低温 DURABLA密封材料,凹凸面水线设计,主次二级密封,此密封材料能有良好的高低温延伸性,不脆裂,低温效果好,能保证长期重复使用。

DURABLA sealing material is used between the left and right valve body, with concave-convex surface waterline design and primary /secondary sealings. This sealing material has good elongation at high and low temperature, not brittle, no crack,and have long lifetime.

4)阀体在外力拉断后的密封度为可设置性,根据不同的介质设计不同的密封率,一般LNG、LN2、LAr建议设置密封率为97%,(使用方也可以自行考虑密封率的问题拆装阀芯密封垫即可达到全密封与泄压要求)。由于低温液体介质在常温大气中容易急剧膨胀,导致软管内压力急剧升高,阀体设计为不全密封,允许部分泄压从而保护软管不会压力过高而爆裂;液氧类易燃易爆设置密封率100%,DN65以上大口径阀体另外设置了放散孔。

The sealing degree of valve body after being breakaway by external force can be set. Different sealing rates are designed according to different media. Normally, The sealing rate of LNG, LN2 and LAr is recommended to be 97%. (Users can also consider the sealing rate.Full sealing and pressure relief requirements can be achieved by removing and installing the valve core gasket.) Because the low temperature liquid media in the room temperature atmosphere is easy to be expanded rapidly and urgently, resulting in a sharp pressure increase in hose, but the valve body is designed to not fully sealed, allowing partial pressure relief to protect the hose from bursting because of too high pressure. The sealing degree of flammable explosive media like Liquid oxygen must set as 100%. The venting hole has been set on the valve body for the size >=DN65.

3.拉断机构:拉断机构既要保证“紧急拉断”时使设备能够自动、快速拉断;又要保证拉断前有“缓冲期”,避免常规操作时出现“拉断”,影响正常装卸作业;装卸鹤管类拉动力根据用户的要求设置相应的拉断装置。

Breakaway Actuator: Breakaway actuator should ensure that the equipment can be automatically and quickly broken away when emergency pulling happened. Also, the actuator must ensure that there is a buffering period before separated, and avoid the occurrence of breakaway during routine operation which may affect normal loading and unloading operations. Corresponding breakway device can be customized according to required pulling force of loading and unloading refueling arm.

1)软管型拉断机构:主要由双头拉断螺栓或单头拉断螺栓、螺母组成。由于金属软管都具有较好的柔性,当槽车超位时逐渐出现张紧并在一定范围内延伸的过程,这个过程提示操作人员“若不采取措施停车,将会出现紧急拉断”,软管的优点就在于自身存在缓冲过程。

Hose-type breakaway actuator

It is mainly composed of double head breaking bolt or single head breaking bolt and nut.

Because metal hose has good flexibility, when the trailer is over the position, it gradually tenses and extends within a certain range. This process reminds of the operator that if you do not take measures to stop, there will be an emergency pull break. The advantage of the hose lies in its own buffering process.

四.工作过程Working process

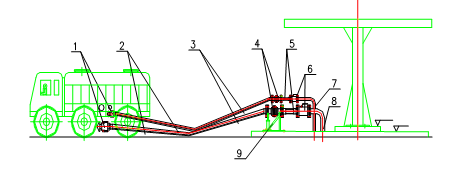

如图 2所示为紧急拉断装置安装在软管工艺管线上的示意图,该套装卸设备主要由软管(金属软管)、快速接头、紧急拉断装置和专用截止阀等组成。

PICTURE 2 shows a schematic diagram of emergency breakaway device installed on the hose processing pipeline. This set of loading and unloading equipment is mainly composed of hose (metal hose), connector, emergency breakaway device and globe valve etc..

1.槽车接口Trailer interface

6.截断阀门Block valves

2.3卸车管线Unloading line

7.8液相管Liquid pipe

4.9.紧急拉断装置Emergency breakaway device

9.支架(可选)Bracket (optional)

5.法兰接口Flange interface

图 2现场布局示意图PICTURE 2 Schematic diagram of site layout

1. 拉断过程

正常装卸时,软管处于松弛自由状态;当槽车或船舶驰离,其接口未与站场设备分离时,软管张紧并逐渐延伸拉长,超出极限范围,拉断螺栓断裂,两端阀体分离。分离后,一半阀体留在管线上,另一半阀体留在软管上,在内部弹簧力的作用下实现密封。

1. Breakaway Process

During normal loading and unloading process, the flexible hose is in a relaxed and free state. When the trailer or ship is driven away and its interface is not separated from the station equipment, the flexible hose tenses and gradually extends and elongates beyond the limit range, the breakaway bolt breaks, and the valve bodies at both ends are separated. After separation, half valve body is left in the line and the other half in the hose, which is sealed by internal spring force.

注意:紧急拉断后,必须迅速关闭站线阀门,卸掉管线压力;在管线排空前不得用外力挤压阀瓣,否则会造成介质批量泄漏,引发安全事故。

Note: after emergency breakaway, the valves on station line must be closed quickly to discharge the pipeline pressure. Do not use external force to squeeze the valve disc before pipeline discharged to empty, otherwise it will cause mass leakage of media and serious accident.

2.拉断后的复原排空管线后进行恢复工作。

紧急拉断装置恢复前检查左右阀体中间密封是否损坏,有损坏则卸下主密封座更换阀体主密封或者阀瓣密封垫;否则只需更换新的拉断螺栓便可。恢复操作时,用通用螺栓锁紧两端阀体,静置5-10分钟,然后依次换上拉断螺栓并拧紧螺母,锁紧拉断螺栓的扭力值为4-5Nm,完成恢复工作。

Recovery after breakaway

Check whether the middle seal between the left and right valve body is damaged before the emergency breakaway device is restored. If there is damage, remove the main seal seat and replace the main seal of the valve body or the valve disc sealing. Otherwise, replace the breakaway bolt. During the recovery operation, lock the valve bodies at both ends with universal bolts, let them standing for 5-10 minutes, and then replace thebreakaway bolts and tighten the nuts with the torque of 4-5Nm and then complete the recovery work.

3.初次进液注意事项及故障排除

初次进液时,务必预冷,待阀体轻微结霜状态是先观察阀体中间连接位置是否有轻微泄露,若有泄露,关闭进液阀门,排出压力,用二把10mm扳手逐步锁紧每个拉断螺栓,切勿用无法掌握力度的大型活动扳手去锁紧,容易导致螺栓断裂。

Notes and troubleshooting for initial liquid injection

Be sure do the precooling, when the body is slightly frosted, observe if there is a slight leakage among body connection. If there is any leakage, shut down the liquid inlet valve and discharge the pressure. Use 2 pcs of10 mm wrenches gradually lock each snap bolt, do not use large adjustable wrench with no grip to tighten, it will cause the bolt fracture.

4.安装方向

拉断阀安装无方向,箭头示意的方向两端皆可连接不同方向。

Installation direction

There is no direction to install the breakaway coupling. Both ends of the arrow direction can be connected in different directions

客服1

客服1